Top 5 TIG Welders Under $1000 (2025 Edition)

Top 5 TIG Welders Under $1000 (2025 Edition): Best Budget AC/DC TIG Machines

Why These 5 TIG Welders Made the List: Methodology and Buying Criteria

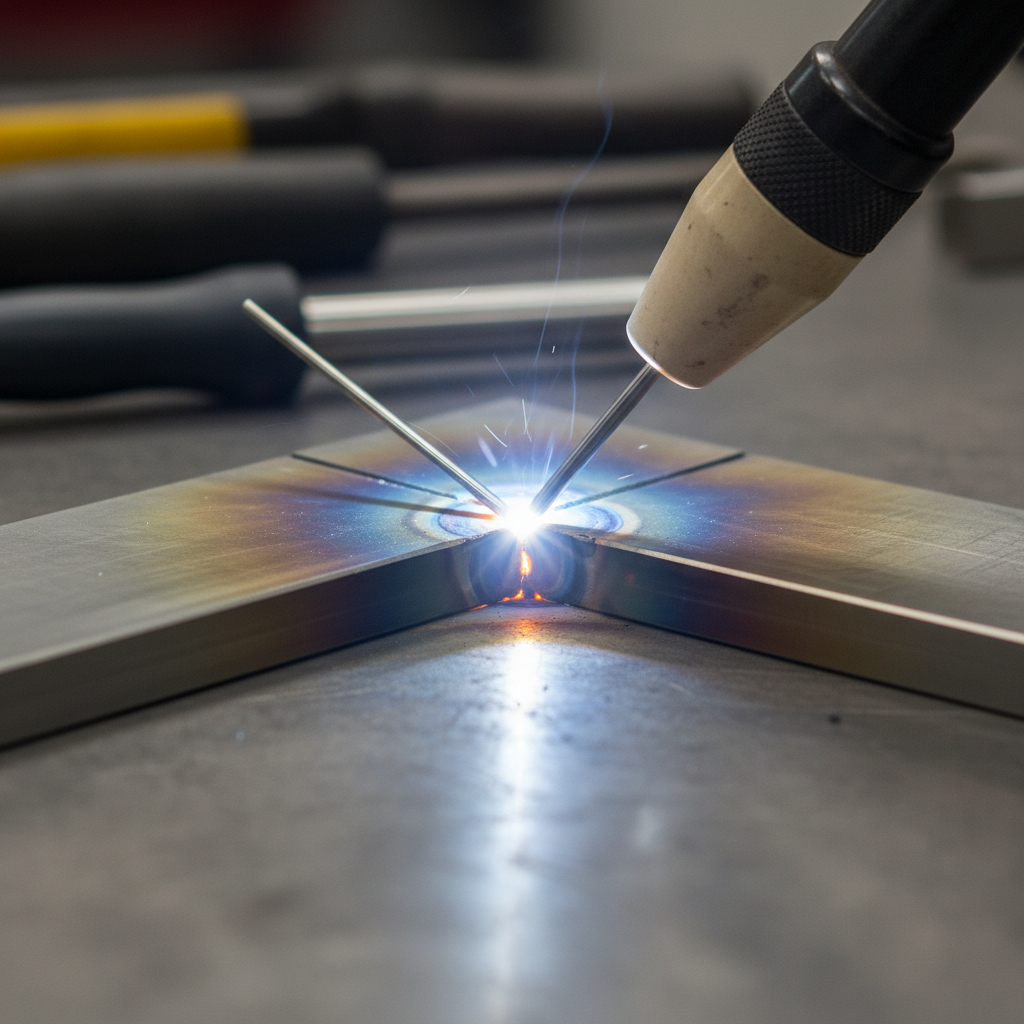

Finding a capable TIG welder under $1000 in 2025 is absolutely possible if you focus on the features that matter most. For this roundup, we prioritized machines that deliver clean arc starts, stable low-amp control for thin material, and AC capability for aluminum. Reliability, parts availability, and useful accessories were also weighed heavily, because a welder is only as good as its torch, pedal, and consumables. Finally, we considered real-world user feedback and shop-proven performance over spec-sheet hype.

Below are the key criteria we used to choose the best TIG welders under $1000. If a machine missed one or more of these, it didn’t make the cut. Use the same checklist as you compare options for your shop to avoid surprises after you unbox the unit.

- AC/DC TIG capability for aluminum and magnesium welding, plus DC TIG for steel and stainless

- High-frequency (HF) start and/or lift-start with smooth arc initiation and no tungsten contamination

- Pulse TIG functions for better heat control on thin materials and stainless steel

- Foot pedal or torch amperage control for precise puddle management

- Dual-voltage 120/240V input for flexibility in garages and job sites

- Usable duty cycle at common shop amperages and robust thermal protection

- Clear, intuitive controls and settings like AC balance, AC frequency, and post-flow

- Solid warranty, responsive support, and readily available consumables

PrimeWeld TIG225X: The All-Rounder for Aluminum and Stainless

The PrimeWeld TIG225X remains a favorite in the sub-$1000 range because it combines power, control, and user-friendly features that genuinely help beginners and skilled fabricators alike. With up to 225 amps on 240V, it offers ample headroom for thicker joints while still maintaining a soft, controllable arc at low amps. AC balance and AC frequency dials let you tune cleaning action on aluminum and sharpen the arc for narrow beads. The front panel is straightforward, the arc is forgiving, and the overall package feels purpose-built for practical fabrication.

Why it stands out

- Stable HF start and smooth low-amp control for thin stainless and sheet aluminum

- AC/DC with adjustable balance and frequency for clean, precise aluminum work

- Useful pulse controls that tame heat input and reduce distortion

- Quality torch and pedal feel in most packages, with common consumables

Potential trade-offs

- Larger footprint than ultra-compact inverters; plan your bench space

- Fan and case noise are typical for the class but audible in small garages

- As with any 225A machine, you’ll need 240V to access full output and duty cycle

Best for home shops and small fab projects, the 225X builds confidence quickly: you can set a mild pulse for thin-wall tubing, switch to AC with a higher frequency for crisp fillets on 6061, and then push amperage on thicker steel without losing arc stability. If you value a well-documented, widely adopted platform with strong community familiarity, this one should top your shortlist.

Everlast PowerTIG 185DV: Dual-Voltage Versatility with Strong Arc Control

Everlast’s PowerTIG 185DV is a compact AC/DC TIG unit that punches above its weight on both 120V and 240V circuits. The arc initiation is clean, and the machine offers the core controls—AC balance, pulse, and post-flow—that unlock high-quality results on aluminum and stainless. Its dual-voltage capability is particularly attractive for users who bounce between a home garage and a mobile setup. Despite the slightly lower maximum amperage compared to bigger units, the 185DV stays composed and consistent in the 30–150A sweet spot where most precision TIG work happens.

- Up to 185A output; ideal for thin to mid-thickness tasks

- HF start, 2T/4T torch control, and pedal support for multiple welding styles

- Clear interface and durable build for daily use in small shops

Where it shines is stability, especially at low currents on stainless and thin aluminum brackets. The 185DV’s pulse functions are easy to dial in, and the arc stays tight without wandering, which helps produce uniform stack-of-dimes beads. If you want a portable, proven machine with enough aluminum performance for brackets, covers, and thin plate—and you frequently need 120V compatibility—this unit is a strong value pick under a grand.

AHP AlphaTIG 203Xi: Aluminum-Friendly Power with Intuitive Controls

The AHP AlphaTIG 203Xi is a popular choice for fabricators who want aluminum capability without the premium price tag. With 200A on tap at 240V, adjustable AC balance, and usable pulse settings, it delivers predictable puddle behavior on a wide range of materials. The control layout is straightforward, helping new TIG welders learn what each setting does without feeling overwhelmed. HF starts are consistent, and the machine’s low-amp finesse on stainless makes it a solid pick for exhaust work and thin-gauge projects.

- AC/DC TIG and stick modes cover most home and light-fab needs

- Clean aluminum beads with adjustable AC balance for oxide control

- Responsive pedal feel in most bundles and common torch consumables

Like many budget inverters, the fan noise and case acoustics are noticeable, and the duty cycle at higher outputs requires reasonable expectations. But the value is hard to ignore: you get the essential TIG toolset—AC tuning, pulse, slope controls—for a price that leaves room for cylinders and a quality helmet. For aluminum-oriented DIYers and hobby fabricators, the 203Xi is a proven, easy-to-recommend choice.

Eastwood TIG 200 AC/DC: Shop-Supported Reliability and Clean Arc

The Eastwood TIG 200 AC/DC offers a well-balanced feature set with a reputation for predictable arc performance and accessible support. Its 200A output handles common shop tasks, while AC balance and pulse help you fine-tune bead quality and heat input. The machine’s control panel is refreshingly simple, minimizing the learning curve for new TIG users. With practical accessories in typical packages and widely available consumables, setup and maintenance are straightforward.

- Reliable HF start and smooth downslope for tidy crater fills

- AC balance and frequency controls to optimize aluminum cleaning and penetration

- Dual-voltage operation for flexible garage and job site use

Where the Eastwood stands out is stability and ease of use rather than raw feature density. It’s a great match for auto restoration, sheet metal, and general fab where arc predictability matters more than extensive menus. If you value a clean arc, intuitive controls, and responsive support in a sub-$1000 package, the TIG 200 AC/DC should be on your radar.

YESWELDER TIG-250P AC/DC: Feature-Rich Controls on a Tight Budget

If you prioritize maximum features per dollar, the YESWELDER TIG-250P AC/DC is one of the most capable budget TIGs available. With up to 250A output on 240V, it has the overhead for thicker work without feeling strained. The interface presents advanced control over AC balance, AC frequency, pulse frequency, and duty, giving you fine control of bead shape, travel speed, and heat input. It may take a session to learn the menu logic, but once dialed in, the arc is surprisingly composed for the price.

- High output ceiling for occasional heavy sections and aluminum plate

- HF start, robust pulse options, and both 2T/4T control modes

- Good value for users who like to experiment with settings to refine results

The trade-off with a feature-dense budget unit is that the interface can feel busy, and consistent pedal response depends on the specific bundle. Still, for welders who want to tune arc characteristics for different joint types and alloys—or who plan to grow into more intricate stainless or aluminum work—the 250P AC/DC offers tremendous headroom without the premium price.

How to Choose the Right Sub-$1000 TIG for Your Work

Start by mapping your most common materials and thicknesses. If aluminum is on the menu, AC is mandatory, and adjustable AC balance and frequency are worth having for better cleaning and arc focus. For stainless and thin sheet, prioritize stable low-amp control, HF start, and pulse. If you’re limited to 120V in some locations, dual-voltage units become more attractive, but remember that their output and duty cycle will be lower on 120V.

Core settings that truly matter

- AC balance: Controls cleaning vs. penetration on aluminum; 65–75% EN is a common starting point

- AC frequency: Higher Hz (100–150) narrows the arc for tight fillets; lower Hz softens it

- Pulse: Use low-frequency pulse (0.5–2 Hz) to pace filler dips on thin stainless

- Slope and post-flow: Smooth crater fills and protect hot tungsten with adequate post-flow

Accessories and consumables to budget for

- Gas lens kit (for a WP-17/CK17 or WP-26 torch) to improve gas coverage and tungsten stick-out

- Foot pedal with a responsive linear feel; consider upgrading if the stock pedal is coarse

- Assorted tungstens: 2% lanthanated for most DC work; zirconiated or ceriated for AC if preferred

- Argon cylinder (100–150 cu ft), flowmeter/regulator, and quality hoses

Setup, Power, and Gas: Getting the Most from a Budget TIG

Even the best TIG under $1000 will disappoint if the setup isn’t dialed. Ensure tight, leak-free gas connections and set your argon flow to match cup size and joint type—often 12–18 CFH with a gas lens indoors is sufficient. Keep your tungsten geometry consistent: a sharp point with a small flat for DC steel and stainless, and a truncated or balled tip with proper AC settings for aluminum. Ground clamp placement matters too; keep it close and on clean metal to reduce arc instability and HF interference.

Power supply matters. On 120V, cap your expectations and focus on thin material with measured duty cycles; save thicker work for 240V where the machine breathes easier. If your shop circuit is borderline, consider a dedicated 240V line and appropriate breaker to avoid nuisance trips when you lean on the pedal. Finally, store filler rods correctly and wipe them before use—contamination often masquerades as “machine problems.”

- Pro tip: On aluminum, start with 120–130 Hz AC frequency and 70% EN, adjust for bead width and cleaning line

- Pro tip: On 16–18 ga stainless lap joints, try 0.8–1.2 Hz pulse, 30–40% peak time, 1:1 background ratio

- Pro tip: For thin sheet, a gas lens and a larger cup (e.g., #8–#12) stabilize shielding and reduce sugaring

Quick Comparison: Which TIG Fits Which User?

Each welder in this list can produce professional results with proper technique, but the best fit depends on your materials, power availability, and learning style. Use the scenarios below to match a machine to your workflow. Remember that package contents and pricing can vary, so confirm the accessories you need—especially foot pedals and torch types—are included.

- PrimeWeld TIG225X: Best overall balance for mixed metal work, frequent aluminum, and learners who want clear controls

- Everlast PowerTIG 185DV: Best for dual-voltage flexibility and stable low-amp stainless on 120V or 240V

- AHP AlphaTIG 203Xi: Best value for aluminum-focused hobbyists who want intuitive controls

- Eastwood TIG 200 AC/DC: Best for users who prioritize predictable arc behavior and straightforward support

- YESWELDER TIG-250P AC/DC: Best for tinkerers who want deep pulse and AC tuning with extra output headroom

Final Verdict: The Best TIG Welder Under $1000 in 2025

If you want a single recommendation that fits most home shops and small fab outfits, the PrimeWeld TIG225X is the standout all-rounder thanks to its stable arc, AC tuning range, and approachable controls. For frequent 120V use or portability, the Everlast PowerTIG 185DV’s dual-voltage performance is hard to beat. Budget-conscious aluminum welders will be well served by the AHP AlphaTIG 203Xi and Eastwood TIG 200 AC/DC, both of which deliver clean, controllable arcs with minimal fuss. And if you want to grow into advanced pulse and AC frequency tuning without overspending, the YESWELDER TIG-250P AC/DC offers exceptional feature density.

Whichever unit you pick, reserve part of your budget for a gas lens kit, quality tungstens, and a comfortable pedal. Those details, combined with sound joint prep and practice, will influence your bead quality as much as the name on the front panel. With the right setup, any of these sub-$1000 TIG welders can produce professional, repeatable results on steel, stainless, and aluminum in 2025.