The Difference Between DCEN And DCEP In TIG Welding

The Difference Between DCEN and DCEP in TIG Welding: What Polarity Really Does

Understanding TIG Polarity: DCEN vs DCEP Defined

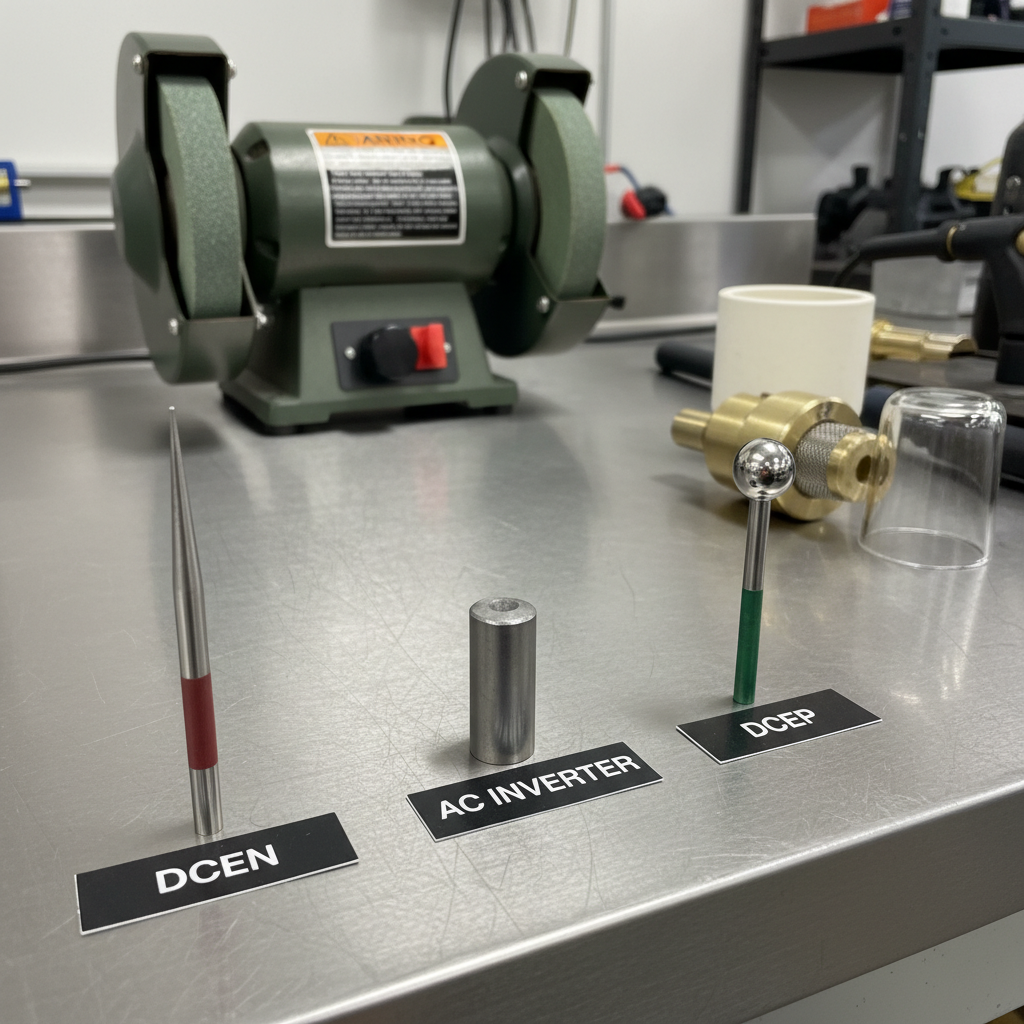

Direct current polarity in TIG (GTAW) is described by where the electrode (tungsten) sits in the electrical circuit. DCEN stands for Direct Current Electrode Negative, sometimes called straight polarity; the torch is negative and the workpiece is positive. DCEP stands for Direct Current Electrode Positive, or reverse polarity; the torch is positive and the workpiece is negative. In DCEN, electrons flow from the tungsten to the work, focusing most heat into the joint and enabling deep penetration. In DCEP, electrons flow from the work to the tungsten, heating the electrode intensely and creating a strong cathodic cleaning effect on the work surface at the expense of penetration.

Heat Distribution, Penetration, and Cleaning Action

Why DCEN Penetrates Deeper

With DCEN, roughly 70–80% of the heat is concentrated at the positive side of the arc—the workpiece—while only 20–30% is on the tungsten. This heat distribution promotes a tighter, more focused arc column and a deeper keyhole, ideal for steels, stainless steels, titanium, nickel alloys, and most copper alloys. Because the tungsten runs cooler, you can use smaller electrode diameters at higher currents without tip meltdown. The result is a narrow, controllable weld pool with strong penetration and minimal tungsten erosion.

Why DCEP Cleans Aluminum

In DCEP, the workpiece is negative (cathode), and positive ions in the plasma bombard the surface, disrupting and “lifting” the oxide film. This cathodic cleaning produces the familiar white frosted etch zone on aluminum but comes with a trade-off: the tungsten becomes the anode and absorbs most of the heat. Consequently, penetration is shallow, the arc is broader, and tungsten overheating or balling occurs quickly at modest amperage. For that reason, DCEP by itself is rarely used for structural welding; it is mainly reserved for specialized cleaning, very thin aluminum foils, or as the EP portion of AC TIG.

- DCEN (electrode negative): deeper penetration, cooler tungsten, minimal cleaning.

- DCEP (electrode positive): strong oxide cleaning, shallow penetration, very hot tungsten.

- AC TIG alternates EN for penetration and EP for cleaning; balance control optimizes the mix.

Choosing and Preparing Tungsten for DCEN and DCEP

Tungsten choice and tip geometry strongly influence arc shape and electrode life. For DCEN on steels and most nonferrous metals (except aluminum oxide-laden surfaces), 2% lanthanated (blue) or 2% ceriated (gray) electrodes are excellent, offering reliable starts and stability at low to moderate currents. 2% thoriated (red) remains common for DC work but is slightly radioactive; handle and grind with appropriate precautions and local regulations in mind. For DCEP or for the EP portion of AC aluminum welding, the tungsten sees extreme heat, so larger diameters and more robust tip shapes are required.

For DCEN, grind lengthwise to form a long taper about 2.5–3 times the diameter, then add a tiny flat to prevent tip splitting. This geometry concentrates the arc for precise, deep fusion. For DCEP-only TIG, use a larger tungsten and let the end form a small, symmetrical ball; even then, current capacity is limited because the electrode runs as the anode. On modern inverter AC for aluminum, a truncated point (not a large ball) often gives a tighter arc and better control while the machine limits EP time to protect the tungsten.

- Approximate current ranges (argon, DCEN): 1/16 in (1.6 mm) up to ~90 A; 3/32 in (2.4 mm) up to ~180–200 A; 1/8 in (3.2 mm) up to ~250–300 A.

- DCEP current capacity is roughly a fraction of DCEN; a 3/32 in (2.4 mm) tungsten may tolerate only ~30–40 A EP before overheating.

- Helium mixes increase heat in the work but can destabilize the arc; adjust flow and tungsten size accordingly.

When to Use DCEN vs DCEP on Real Jobs

For almost all TIG welding on ferrous and high-temperature alloys, DCEN is the default choice. It offers efficient heat input, crisp arc control, and strong fusion with minimal electrode stress. DCEP is a niche setting that shines primarily for cathodic cleaning on aluminum surfaces or extremely thin aluminum sheet where penetration must be carefully limited. Most production aluminum is welded using AC, which cycles between EN (penetration) and EP (cleaning) and is adjustable on inverter machines.

- Choose DCEN for: carbon steel, stainless steel, titanium, nickel alloys, most copper alloys, and structural joints where penetration matters.

- Use DCEP briefly to: remove a stubborn oxide skin on aluminum, touch up an etch zone, or weld ultra-thin aluminum foils at very low amperage.

- Select AC for: general aluminum and magnesium welding; tune AC balance to ~65–75% EN on inverters for good penetration with sufficient cleaning.

- For thick aluminum or dirty castings: AC with increased cleaning time (more EP) and proper precleaning is typically more effective than DCEP alone.

Setting Up Your TIG Machine for the Right Polarity

Machine setup depends on your power source layout, but the fundamentals are consistent. For DCEN, connect the TIG torch lead to the negative (-) terminal and clamp the work lead to the positive (+) terminal; for DCEP, reverse these connections. Select DC on the process switch and choose high-frequency (HF) start if available to prevent tungsten contamination; lift-arc can work but risks touching the tip. Be sure to set adequate preflow and postflow gas to protect the tungsten and the weld pool during start and crater fill.

- Confirm polarity: DCEN (torch - / work +) for most metals; DCEP (torch + / work -) only for specialized cleaning or very thin aluminum.

- Set current mode: DC for steels; AC for aluminum and magnesium unless you intentionally use DCEP for a specific task.

- Choose tungsten type and size: lanthanated or ceriated for DCEN; larger diameter for any EP exposure.

- Prepare tip: long taper with small flat for DCEN; small, smooth ball for DCEP-only; truncated point for inverter AC.

- Install a gas lens and appropriate cup (e.g., #7 to #12 depending on joint and stickout) to improve shielding and arc stability.

- Set shielding gas: pure argon is the baseline; 15–20 cfh (7–10 L/min) to start, adjusting for cup size and gas lens. Increase slightly for helium mixes or larger gas cups.

- Typical starting settings (mild steel, DCEN, 1/8 in joint): 3/32 in tungsten, 120–140 A, 15–18 cfh argon, 1/2 in stickout with gas lens.

- Typical starting settings (aluminum, AC inverter, 1/8 in plate): 3/32 in tungsten, 130–160 A, 65–75% EN balance, 120 Hz, 18–22 cfh argon.

- If trying DCEP for cleaning: use a large tungsten (e.g., 1/8 in), limit to ~20–30 A, and monitor electrode temperature closely.

Shielding Gas, Arc Starts, and Torch Technique by Polarity

Shielding gas choice influences heat input and arc stability. Pure argon offers smooth starts and a stable arc in both DCEN and DCEP, while helium or Ar/He blends can boost heat in the work for thicker sections or faster travel; however, helium makes arc starting more difficult and can widen the arc. HF start is strongly recommended for preserving tip geometry at DCEN and for reliable ignition; scratch start risks tungsten contamination and arc wander. Maintain a 10–15° torch angle and a short, consistent arc length to tighten the arc and limit porosity, especially important with the wider arc tendencies of DCEP and AC EP.

- DCEN technique: keep the arc short (approximately one tungsten diameter), push or slight push angle to improve gas coverage, and add filler into the leading edge of the puddle.

- DCEP technique: expect a wider, softer arc; reduce current, increase tungsten size, shorten arc length, and watch the etch zone to avoid over-cleaning.

- With AC on aluminum: adjust balance to minimize excessive etch width; too much EP overheats the tungsten and dulls arc focus.

- Consider a gas lens and larger cup for better coverage when using extended stickout for visibility on fillets or inside corners.

Troubleshooting by Polarity: Symptoms and Fixes

Polarity mistakes or mismatched setup often show up as distinctive problems in the weld pool or electrode. DCEN errors usually involve tungsten contamination from long arcs or incorrect grind, arc wander from inadequate gas coverage or magnetic arc blow, and undercut from excessive travel speed. DCEP problems cluster around rapid tungsten overheating, uncontrolled ball growth, shallow penetration, and an overly wide etch zone on aluminum. Use the following quick checks to stabilize your process before chasing more complex variables.

For DCEN:

- Tungsten contamination or spitting: shorten arc length, use HF start, add a small flat to the point, and verify gas coverage with a gas lens.

- Arc wandering: grind longitudinally, not around the circumference; reduce stickout; increase cup size or flow; eliminate drafts.

- Lack of penetration: increase amperage or preheat, slow travel, or move to helium mix; confirm joint fit-up and cleanliness.

- Undercut or narrow bead: reduce travel speed and torch angle; increase filler deposition rate; ensure adequate heat input.

For DCEP:

- Tungsten overheating/balling excessively: drop amperage, step up tungsten size, increase EN time by switching to AC with more EN, and improve cooling pauses.

- Shallow penetration: switch to DCEN or AC; if DCEP is required, accept limited penetration and tailor joint design accordingly.

- Overly wide etch zone: reduce EP exposure (use AC balance), lower current, or increase travel speed to confine cleaning.

- Unstable arc starts: use HF start; ensure polished, symmetrical ball and correct gas flow; avoid helium-rich mixes at very low amps.

FAQs About DCEN, DCEP, and AC Balance in TIG Welding

Welders frequently ask how polarity interacts with alloy, joint type, and modern inverter features. While DCEN remains the backbone for most TIG work, understanding when and why EP helps can improve results on challenging aluminum surfaces. Inverter AC balance and frequency controls reduce the need for dedicated DCEP by “dialing in” just enough cleaning while preserving penetration and electrode life. These quick answers address common confusions.

- Q: Can I TIG weld stainless with DCEP? A: No—use DCEN for penetration and arc focus; DCEP will overheat the tungsten and undercut penetration.

- Q: Can aluminum be welded with DCEN only? A: It’s possible with rigorous mechanical/chemical cleaning and often helium mixes, but AC is preferred for consistent oxide removal.

- Q: Why is AC better than DCEP on aluminum? A: AC gives you EP for cleaning and EN for penetration, and balance control limits tungsten heating while maintaining a clean puddle.

- Q: What’s “straight” vs “reverse” polarity? A: Straight polarity is DCEN (torch -), reverse polarity is DCEP (torch +).

- Q: How does AC balance affect tungsten life? A: More EN (e.g., 65–75%) reduces EP time, keeping the tungsten cooler and the arc tighter; too much EP enlarges the ball and blunts the arc.

- Q: Does helium change the best polarity? A: No, but helium increases heat in the work and can help penetration on DCEN; use higher flow and expect harder starts.

- Q: What tip shape works best on inverters for aluminum? A: A truncated point resists balling, tightens the arc, and works well with EN-heavy AC balance.

In short, DCEN is the go-to TIG polarity for strong penetration and a sharp, controllable arc on most metals. DCEP is a powerful but limited tool for cathodic cleaning and delicate, low-penetration tasks, more commonly leveraged as the EP half of AC on aluminum. Understand how heat, arc shape, and tungsten behavior shift with polarity, and you’ll choose settings confidently, produce cleaner welds, and extend electrode life.