How To Clean Metal For TIG Welding Success

How to Clean Metal for TIG Welding Success

Understanding the Importance of Metal Cleanliness in TIG Welding

Before starting the TIG welding process, it’s crucial to understand why metal cleanliness is fundamental. Clean metal not only ensures strong and durable welds but also prevents contamination that can lead to defective joints. Contaminants like oil, rust, and oxidation can affect the weld’s quality, resulting in imperfections or even failures. Maintaining clean surfaces enhances the weld bead's appearance and mechanical properties, allowing for a higher quality finish essential for critical applications.

Gathering the Right Tools and Materials for Cleaning Metal

To effectively clean metal before TIG welding, the right tools and materials are necessary. Using the proper equipment can significantly reduce preparation time and increase the quality of the weld. It’s vital to have these items readily available in your workspace.

- Wire brushes or stainless steel brushes

- Industrial-grade solvents or acetone

- Sandpaper or abrasive pads

- Clean, lint-free cloths

- Personal protective equipment (PPE) like gloves and goggles

Steps to Clean Different Types of Metal

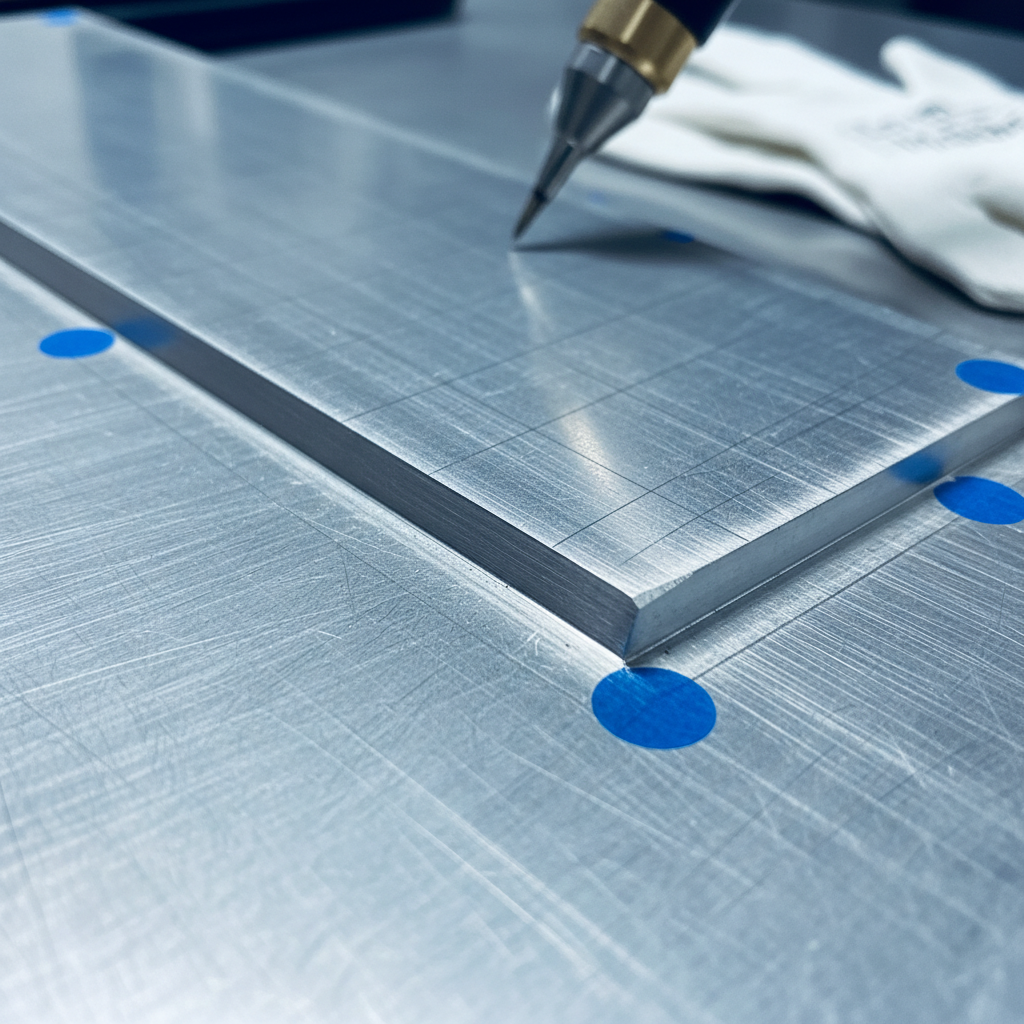

Cleaning Aluminum for TIG Welding

Aluminum is a sensitive metal that requires special attention when cleaning. Begin by using a stainless steel wire brush to remove the top layer of aluminum oxide. This layer forms quickly on aluminum and can impede the welding process. After brushing, apply a solvent like acetone to remove any grease or contaminant residue. Finally, wipe the surface with a clean, lint-free cloth.

Cleaning Steel and Stainless Steel

For steel or stainless steel, the procedure includes different steps. Use an abrasive pad or sandpaper to remove rust and any existing coatings. Follow up by wiping the metal with a solvent-soaked cloth to eliminate oils and contaminants. Ensure that the cleaning solution evaporates entirely before proceeding to the welding stage.

Techniques for Effective Deburring and Edge Preparation

Deburring and preparing edges are essential for clean weld surfaces. Burrs or sharp edges can trap contaminants, affecting the metal adhesion when welding. Use a deburring tool or a file to smoothen edges. Making sure that all sides of the weld joint are prepared helps in achieving a cleaner and stronger weld.

Ensuring a Clean Environment for Welding

Maintaining a clean working environment is as important as cleaning the metal itself. Dirt and dust in the welding area can settle on prepared surfaces, leading to contamination. Regularly clean your workspace to reduce the risk of airborne particles affecting metal surfaces. Use protective coverings for cleaned pieces if immediate welding is not possible.

Final Quality Checks Before Welding

Before proceeding with the welding process, conduct a final check to ensure the metal surfaces are completely clean. Look for any remaining residues that might not be apparent to a casual glance. This last inspection can save time and resources by preventing errors early in the process. A thorough quality check guarantees that the metal is in the best condition for a successful TIG weld.

Cleaning metal properly involves a sequence of well-defined steps and attention to detail, each contributing to the quality of the TIG weld. By adhering to these guidelines, you can enhance both the strength and appearance of your welds, ensuring professional-grade results every time.