AC Vs DC In TIG Welding: What’s The Difference?

AC vs DC in TIG Welding: What’s the Difference?

Understanding TIG Welding and its Applications

TIG welding, also known as Tungsten Inert Gas welding, is a precise and versatile welding technique used extensively in various industries. This method is preferred for its ability to produce high-quality, aesthetically pleasing welds on a range of materials, including stainless steel, aluminum, and copper. The welding process involves using a non-consumable tungsten electrode to create the weld. To ensure the creation of strong and clean welds, it is crucial to understand the differences between alternating current (AC) and direct current (DC) settings in TIG welding.

What is Alternating Current (AC) in TIG Welding?

Alternating Current (AC) in TIG welding is characterized by a current that changes direction periodically. This is especially useful when welding non-ferrous metals like aluminum and magnesium. These metals often have an oxide layer that requires a cleaning action for effective welding. The AC provides this cleaning action by continuously reversing the current's direction, which helps break up the oxide layer. This ensures better penetration and cleaner welds.

Advantages of AC in TIG Welding

- Offers cleaning action that removes oxide layers from aluminum surfaces.

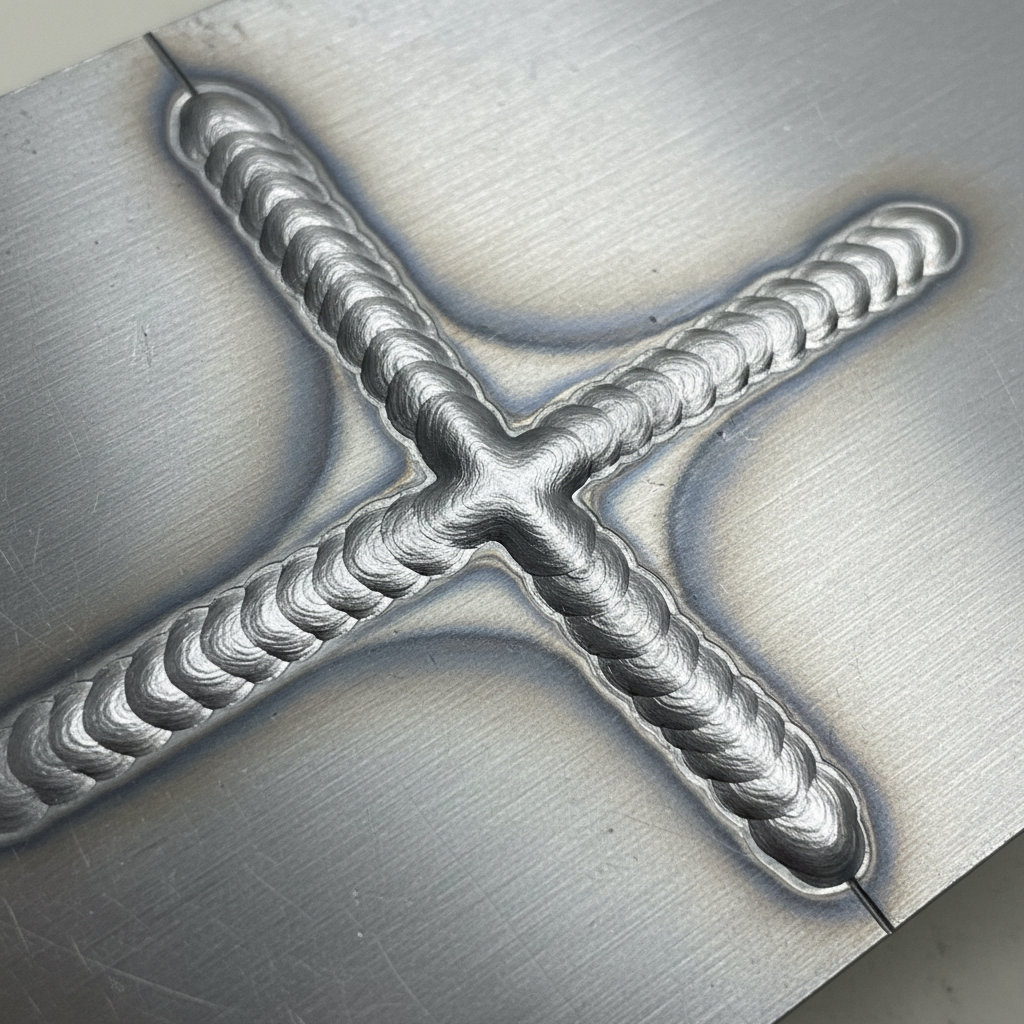

- Enables excellent weld bead appearance on aluminum and magnesium.

- Provides stable arc and precise control over weld pool.

Understanding Direct Current (DC) in TIG Welding

Direct Current (DC) in TIG welding provides a continuous flow of current in one direction. This setting is typically used for welding ferrous metals, such as steel and stainless steel. DC TIG welding allows for deep penetration and precise control of the weld pool, which is essential for achieving strong and durable welds. Welders often prefer the DC mode for its ability to create smoother, cleaner finishes on metals that do not require oxide cleaning actions.

Benefits of DC in TIG Welding

- Delivers deeper penetration and stronger welds in ferrous metals.

- Offers smoother and more stable arc compared to AC.

- Enhances control over the weld pool for precision work.

Selecting the Right Power Source for Your TIG Welding Projects

Choosing between AC and DC depends largely on the type of materials you are working with and the desired outcome of the weld. Projects that involve aluminum or magnesium typically require AC due to the need for oxide layer cleaning. Conversely, when working with steel and stainless steel, DC is generally the preferred choice, offering deeper penetration and a more stable arc.

Practical Tips for Optimizing Your Weld Beads

Regardless of whether you are using AC or DC, applying some practical welding techniques can greatly enhance the quality of your welds. Here are a few tips:

- Ensure the tungsten electrode is properly sharpened for precise arc control.

- Adjust your amperage settings according to the thickness of the material.

- Maintain a consistent torch angle and speed for uniform weld beads.

- Use the correct shielding gas to prevent contamination and ensure weld quality.

Troubleshooting Common TIG Welding Issues

Successfully executing TIG welding depends not only on the correct use of AC or DC but also on addressing potential welding issues that may arise. Some common problems include poor arc starts, contamination of the weld pool, and incorrect penetration. Learning to troubleshoot these issues effectively can minimize downtime and enhance the quality of the finished weld.

Effective Solutions

- Check for proper grounding and connections to avoid weak arc starts.

- Ensure that the workpiece and electrode are clean prior to welding to prevent contamination.

- Adjust amperage and travel speed to achieve desired penetration levels.

Conclusion: Making an Informed Choice

Understanding the distinct roles of AC and DC in TIG welding is essential for executing successful, high-quality projects. AC is your best bet for welding non-ferrous metals like aluminum, while DC excels in applications involving ferrous metals such as steel. With careful consideration and application of proper techniques, your TIG welding efforts will undoubtedly yield professional and durable results. Remember, the key lies in choosing the right current type that aligns with your specific welding needs.